Pallets are a vital factor in packaging systems and logistical processes. Therefore the ultimate goal when stacking pallet loads is to create the most uniform shape possible; when done correctly, the products will be easier to wrap together. Unfortunately, getting a perfectly shaped pallet is better said than done.

Let's continue reading to learn more about the three types of pallet loads and the most suitable stretch wrap material for each load.

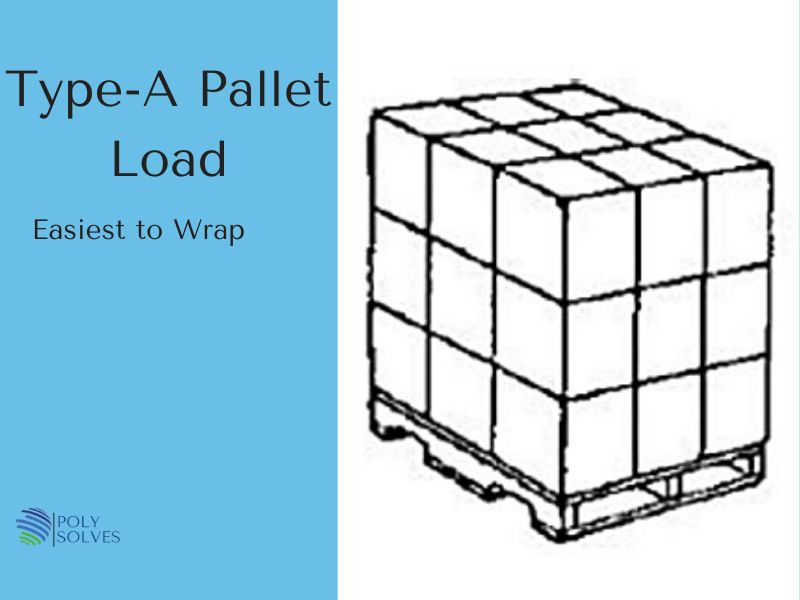

A-Types of Pallet Loads

Type-A pallet loads are uniform in shape, and the load size closely matches the pallet size, which makes them the most manageable loads to wrap, as there are only a few puncture points.

The consistent vertical and horizontal edges of type-A pallet load make fewer areas exist that can potentially tear or damage the stretch film. Therefore, lightweight strapping materials or lower gauges of the stretch film will be best to use when wrapping this type of pallet load.

B-Types of Pallet Loads

Type-B pallet loads are usually less uniform than type-A loads. Their stacking pattern may be irregular, and the load size may not match the pallet size. Several film puncture points exist, which require a more sophisticated film.

Due to the irregularity of type-B pallet load, you will typically need a stretch film of a higher gauge. The standard stretch wrap wouldn't be ideal for type-B pallet loads due to the chances of a puncture.

C-Types of Pallet Loads

Type-C pallet loads are the least uniform in shape compared to type-A and B. Therefore, they are the most difficult to stretch, wrap or strap. These loads feature numerous sections where irregular or sharp edges poke out from the overall shape. It is challenging to secure this pallet load because the risk of stretch wrap tearing or strap breaking is high.

Type-C pallet load has poor weight distribution; it is either very light or heavy, making it very unstable. These difficult-to-handle loads usually require special attention to wrap without causing the pallet to collapse. Type-C pallet load will need the strongest stretch film with a higher gauge that can handle the load's weight and shape.

Choosing the correct stretch wrap thickness

Stretch wrap thickness or gauge is crucial when deciding which is best suited for your business need, and it can be challenging. But don't you worry; Poly Solves can help make it easier. We offer a wide range of stretch wraps, varying in thickness and size, that is suitable for your business need.

Our expert composed a guide with the most common stretch wrap gauges and how each is typically used to help you make the best decision.

60 gauge stretch wrap is the most common film that can support uniform loads up to 1,800 lbs. Most suitable for type-A pallet load.

70 to 80 stretch wrap gauge delivers suitability for loads ranging from 2,200 up to 2,400 lbs. Most suitable for type-B pallet load.

90,100 & 120 stretch wrap thickness films are much more resistant to tears, punctures, and other damage. Most suitable for type-C pallet load.

Got Questions? Contact Poly Solves LLC

When choosing the best gauge of stretch wrap for your pallet load, it's crucial to get it right. And the experts at Poly Solves LLC can help you make the best decision.

Contact Poly Solves LLC today.

Comments